Drug Free Workplace

WindCom has a zero tolerance level for drug and alcohol use. Technicians are pre-screened upon employment and all have agreed to random drug tests. The company encourages everyone to notify the office of suspicious behavior that might be signs of intoxication so that the tech can be tested. The drug free policy also carries on after working hours when using a company vehicle.

In House Training

WindCom has developed a comprehensive in house training program which has been continuously upgraded over the past 8 years. Required certifications include, First Aid/CPR, OSHA 10, Suspended Scaffold Safety, Self-Rescue, Lockout/Tag out. Also included is fire safety and proper use and disposal of chemicals. The week long training goes into depth for many other subjects such as electrical safety, hand tool safety, platform rigging and use of all of WindCom forms such as accident reporting, near miss reporting.

Daily Routine

Each morning before work starts at the tailgate meeting, every field crew completes a JSA report where they look for possible hazards in that day’s work. Identifying the risks is the first step. Then a plan to mediate the risks follow. When these are reviewed by the EHS manager, he is able to make sure that the technicians are doing a good job of looking for all hazards. If shortcomings are found, coaching will enable the techs to improve. Every morning the platform is inspected for cracks or other defects. Then the platform is raised and the block stops are tested. Nothing is left to chance.

Rigging

Every turbine has a rigging plan for each of our platforms. Each morning the rigging is inspected if it has been left from the previous day. If the turbine is one we have not seen before, we personally visit the site and create a rigging plan before the techs arrive. This also gives us a chance to discuss with the site manager any hazards peculiar to that site.

Near Miss Program

Everyone in the company is encouraged to report near misses. This is one way in which we continuously improve our safety program. All of the techs are then alerted to the incident and later the safety committee discusses them for amendments to the safety training every technician receives. Even in our work instructions for every repair, safety is incorporated including PPE necessary for each step.

360° Platform

Work Cage

Confined Space Entry

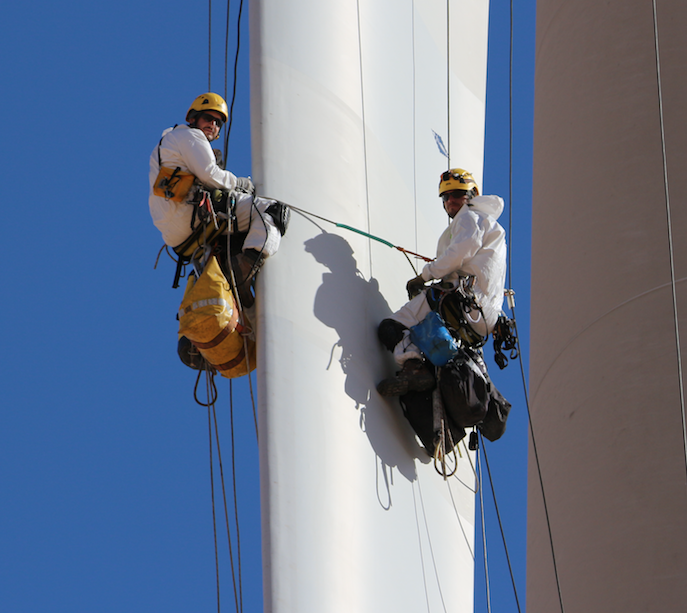

Rope Access

![]()

Mobile-Friendly Interface

![]()

Comprehensive Project Database

![]()

Basis for predictive maintenance

The blade maintenance process is electronically documented from day one starting with a blade assessment report.

Engineers review the assessment report and provide custom work instructions and specifications for the damage repairs.

The engineer monitors progress to ensure correct execution by reviewing technician uploads including data and photos per the work instructions. Upon completion, all projects are reviewed by the engineer before technicians leave the site.

Reports are auto generated for the customer. All data and photos are accessible to create customized reports and downloadable by the customer for their server.

Ensure the maximum lifetime for customer's blades through focusing on high levels of technical competence, innovation and flexibility to rapidly attend the most demanding blade repairs in the wind global market with safety, integrity and respect.

5151 World Houston Parkway, Suite 100 Houston, TX 77032

Copyright © 2024 Wind Composite Services Group, LLC